We’re leading the charge towards sustainability in the steel industry, offering eco-friendly solutions that also save you money. We keep casters running by offering caster segment rebuilds, roll refurbishment, smart rotary joints, split bearing housings, and bearing reclaim services. Also, we keep hot strips rolling by offering table roll repair, coiler roll repair, roll assembly, chock reclaim, and bearing reclaim services. Together, our services cut carbon emissions and costs simultaneously.

Servicing the steel industry nationwide from our locations in Alsip, IL, Gary, IN, Granite City, IL, and Birmingham, AL, we’re your partners for a greener, more profitable future.

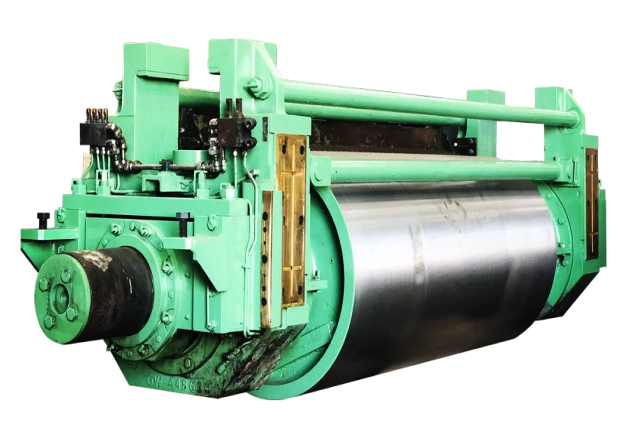

Our scopes range from simple, efficient repairs to complete rebuilds that include frame straightening, roll overlaying, and pipe replacement. Our resourcefulness saves our customers time and money while eliminating the potential emissions from manufacturing new parts.

Our proprietary overlays and manufacturing processes result in more tonnage produced for our steel mill customers. Instead of purchasing new rolls, we work with steel mills to refurbish and re-use their roll fleet. This saves time, money, and reduces the steel industry’s carbon footprint.

Expensive bearings are discarded daily because it is assumed their reliability has expired. The cost of a re-used bearing can be as low as 20% of the cost of a new bearing. Not only does this service save money, but it also promotes reusability with our customers.

This leads to cost savings and quicker turnaround times when rebuilding caster segments and roll assemblies. In the end, quicker lead times mean more uptime for our steel customers.

This allows our customers to catch possible issues before they arise. If problems do occur, our smart rotary joint allows for a more efficient failure analysis. Machine monitoring is the future of the steel industry, and our smart rotary joint is just the beginning.

We are one of the few domestic sources with experience manufacturing these intricate assemblies. Our dedication to quality ensures our bearing housings maintain the very close tolerances needed for the application.

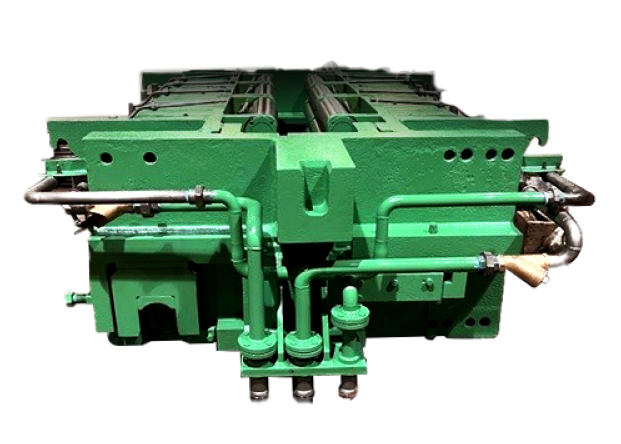

Caster Maintenance is the #1 domestic source for caster segment repair in the U.S. and Canada.

Our scopes range from simple, efficient repairs to complete rebuilds that include frame straightening, roll overlaying, and pipe replacement. Our resourcefulness saves our customers time and money while eliminating the potential emissions from manufacturing new parts.

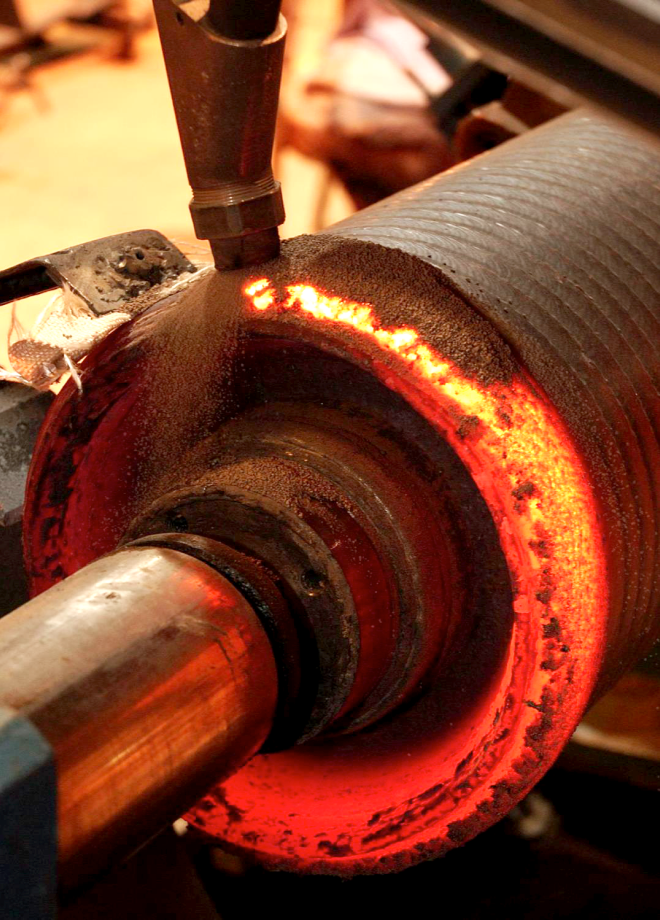

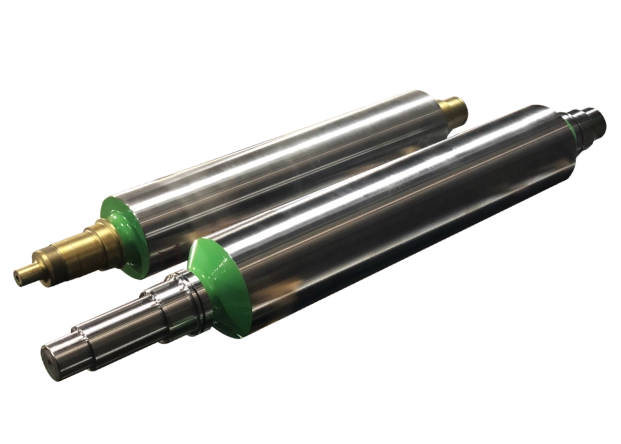

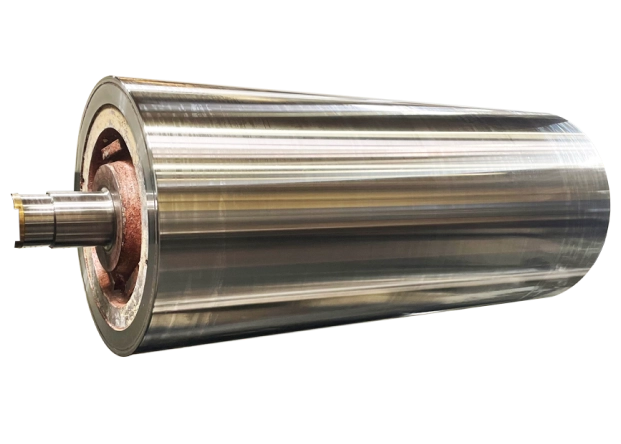

Kocsis is the #1 domestic source for refurbishing and manufacturing steel rolls.

Our proprietary overlays and manufacturing processes result in more tonnage produced for our steel mill customers. Instead of purchasing new rolls, we work with steel mills to refurbish and re-use their roll fleet. This saves time, money, and reduces the steel industry’s carbon footprint.

Caster Maintenance’s proprietary bearing reclaim service allows our customers to re-use their bearings for multiple campaigns.

Expensive bearings are discarded daily because it is assumed their reliability has expired. The cost of a re-used bearing can be as low as 20% of the cost of a new bearing. Not only does this service save money, but it also promotes reusability with our customers.

Caster Maintenance’s bearing housing reclaim service allows steel mills to re-use their bearings housings for multiple campaigns.

This leads to cost savings and quicker turnaround times when rebuilding caster segments and roll assemblies. In the end, quicker lead times mean more uptime for our steel customers.

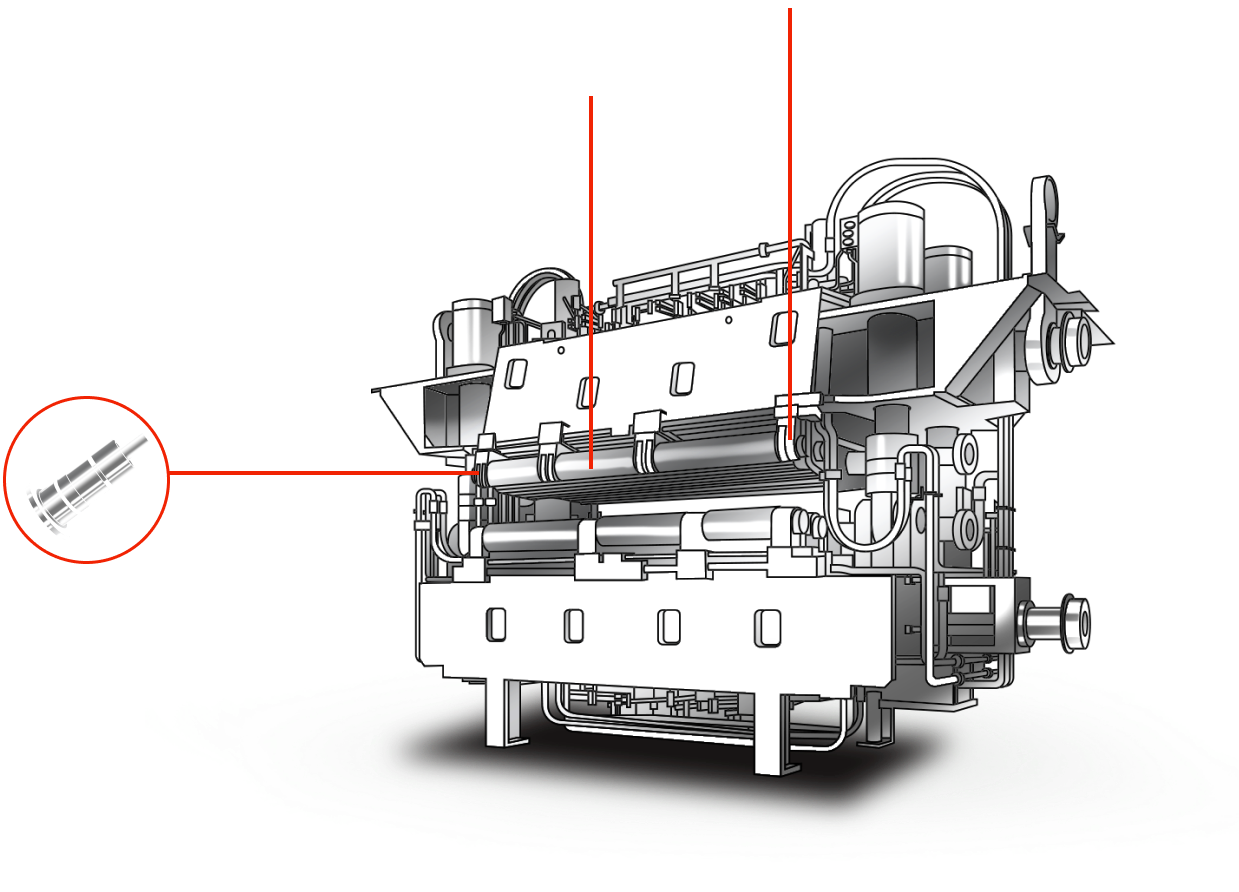

Kocsis smart rotary joints measure the flow and temperature of water to caster rolls.

This allows our customers to catch possible issues before they arise. If problems do occur, our smart rotary joint allows for a more efficient failure analysis. Machine monitoring is the future of the steel industry, and our smart rotary joint is just the beginning.

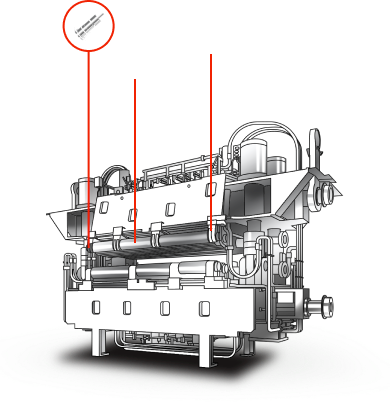

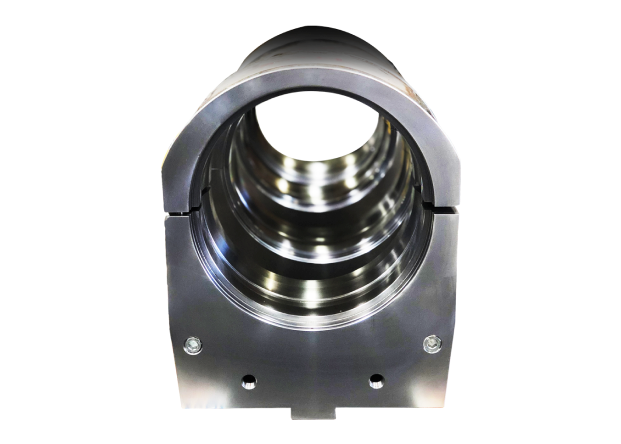

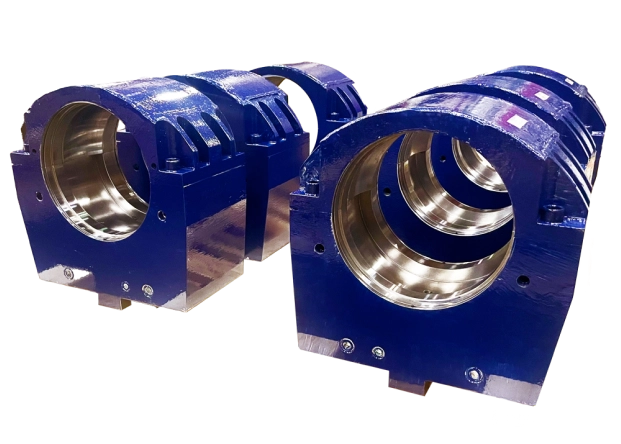

Kocsis manufactures split water-cooled bearing housings for continuous casting applications.

We are one of the few domestic sources with experience manufacturing these intricate assemblies. Our dedication to quality ensures our bearing housings maintain the very close tolerances needed for the application.

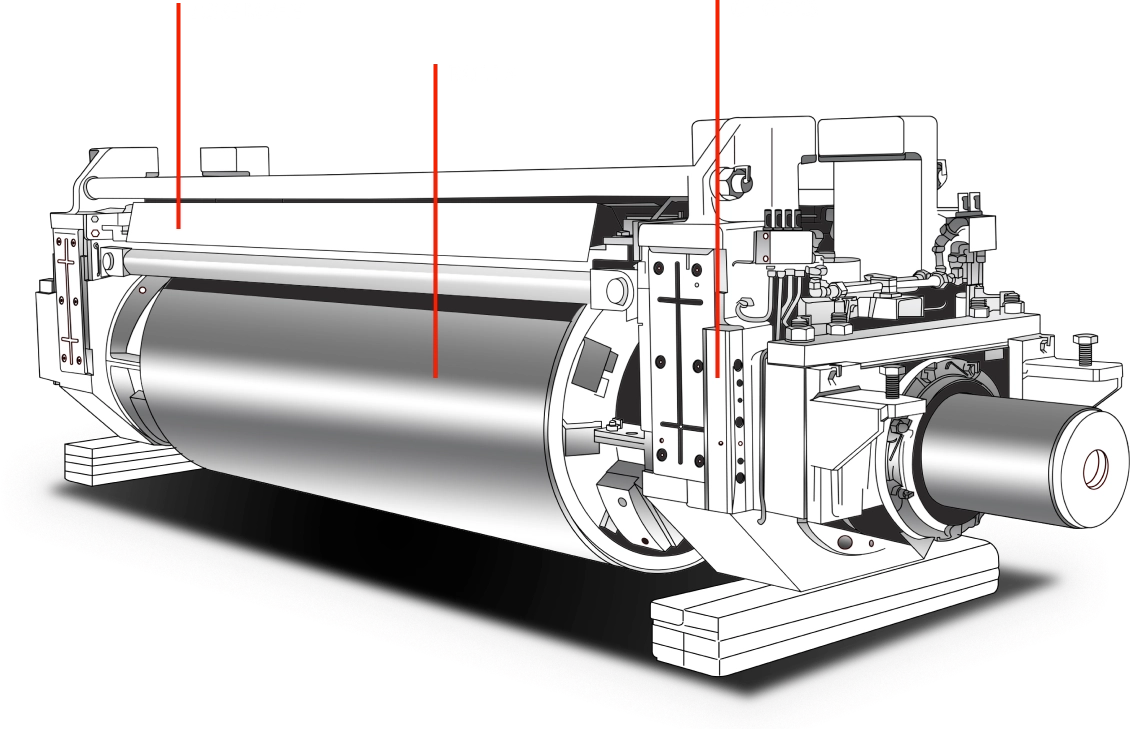

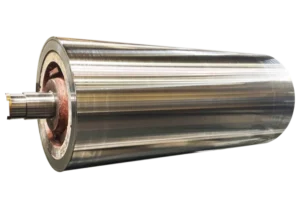

Anatomy of a Roll Assembly

Instead of purchasing new rolls, we save our customers time and money by repairing their existing table roll fleet. This also saves energy and reduces the steel industry’s carbon footprint.

Kocsis and Caster Maintenance’s partnership ensures ample capacity to meet mill assembly requirements. From bearing reclaim to bearing housing manufacturing to final assembly, we can manage any roll assembly program.

Our large machining capacity allows us to take on big chock projects. Our inspection team ensures proper documentation is maintained upon incoming inspection. Finally, our talented manufacturing team ensures our chocks meet customer requirements.

Expensive bearings are discarded daily because it is assumed their reliability has expired. The cost of a re-used bearing can be as low as 20% of the cost of a new bearing. Not only does this service save money, but it also promotes reusability with our customers.

Kocsis extends the life of table rolls by using our proprietary welding wires and manufacturing processes.

Instead of purchasing new rolls, we save our customers time and money by repairing their existing table roll fleet. This also saves energy and reduces the steel industry’s carbon footprint.

Kocsis has been welding pinch and wrapper rolls for over 20 years. We understand the importance of coiler roll weld quality.

We offer a range of services including roll re-grinds, weld repair, assembly, and inventory management. Our proprietary tool steel wires and manufacturing processes ensure the highest roll quality. Our goal is to keep hot strips rolling.

Not only does Kocsis repair bare rolls, but we also supply turnkey table and coiler roll assemblies.

Kocsis and Caster Maintenance’s partnership ensures ample capacity to meet mill assembly requirements. From bearing reclaim to bearing housing manufacturing to final assembly, we can manage any roll assembly program.

Kocsis and Caster Maintenance have years of experience repairing various sizes of chocks.

Our large machining capacity allows us to take on big chock projects. Our inspection team ensures proper documentation is maintained upon incoming inspection. Finally, our talented manufacturing team ensures our chocks meet customer requirements.

Caster Maintenance’s proprietary bearing reclaim service allows hot strips to re-use their bearings for multiple campaigns.

Expensive bearings are discarded daily because it is assumed their reliability has expired. The cost of a re-used bearing can be as low as 20% of the cost of a new bearing. Not only does this service save money, but it also promotes reusability with our customers.